Enhancing Equipment Reliability through Data-Driven Insights

Accelerate Implementation of Predictive Maintenance with No-code Environment

Predictive Maintenance Accelerator

This Predictive Maintenance AI-ML model helps industries and organisations to predict when equipment is likely to fail.

By leveraging these predictions which identifies potential equipment issues before they become critical, organisations can optimize maintenance schedules and reduce the risk of unexpected downtime, reduce the cost and disruption of equipment downtime, improve overall equipment reliability, and extend the life of their assets.

Why Predictive Maintenance Accelerator?

Predictive Maintenance Accelerator provides pre-built components, such as machine learning predictions and business insights that can be configured and customized to meet the specific needs of an organization and can be integrated with existing maintenance systems to provide a seamless solution. By using this Accelerator, organizations can reduce the time and can focus on using the insights generated to improve equipment reliability and reduce maintenance costs.

Downtime Risk: MLAAS helps predicting equipment failures, organizations can reduce the risk of unexpected downtime.

Improve Overall Equipment: MLAAS offers performing maintenance before they occur organizations can improve overall equipment reliability.

Lower Maintenance Costs: MLAAS can help reduce the cost of maintenance by optimizing maintenance schedules.

Increased Asset Lifespan: Regular maintenance performed promptly can help extend the lifespan of equipment assets.

Improved Safety: By reducing the risk of equipment failure, MLAAS can help improve safety in the workplace.

Better Decision-Making: MLAAS provides organizations with valuable data and insights that can inform decision-making in maintenance scheduling.

Increased Efficiency: By reducing the risk of unexpected downtime, MLAAS can help organizations improve operational efficiency and increase productivity.

Reduction in total maintenance cost

Reduction in sudden and complete breakdowns

Imporved equipment productivity

Reduction in unplanned downtime

Use Cases of Predictive Maintenance

The use of Predictive Maintenance AI-ML model in any industry can help organizations reduce costs, improve efficiency, and increase equipment reliability and safety.

Manufacturing: MLAAS is used to monitor and predict the failure of the production lines equipment.

Transportation: MLAAS is used to monitor and predict the failure of vehicles.

Healthcare: MLAAS is used to monitor and predict the failure of medical equipment, such as MRI machines and ventilators.

Agriculture: MLAAS is used to monitor and predict the failure of farming equipment, such as tractors, combines, and irrigation systems.

Mining: MLAAS is used to monitor and predict the failure of heavy machinery, including drilling and excavation equipment.

About Predictive Maintenance Dashboard

- Parameters: Used to filter the data based on the year, month, and records that are related to failure and non-failure.

- Insights: These visual displays a single value or static value of the field which we select, it is highly customizable and can filter this data as the filters are applied.

- Model differentiation by rotation: This shows the difference between all the categories i.e., models, comparing them with the Rotational speed of each model.

- Machines with failure and No-failure count: This donut chart visually displays the difference between the number of failures and non-failures, along with their respective percentages.

- Voltage variations across models: This illustration depicts the comparison of the models based on their voltage differences.

- Machine longevity: This Line chart shows the graph of the life span of each machine.

- Vibration disparities between models: This column chart presents a comprehensive analysis of the model's high vibration levels, based on the data.

- Pressure dissimilarities across models: This is the same as Vibration disparities, used to compare types of models based on pressure.

- Machine quantity by model: Comparing all types of models based on the machine type.

Video

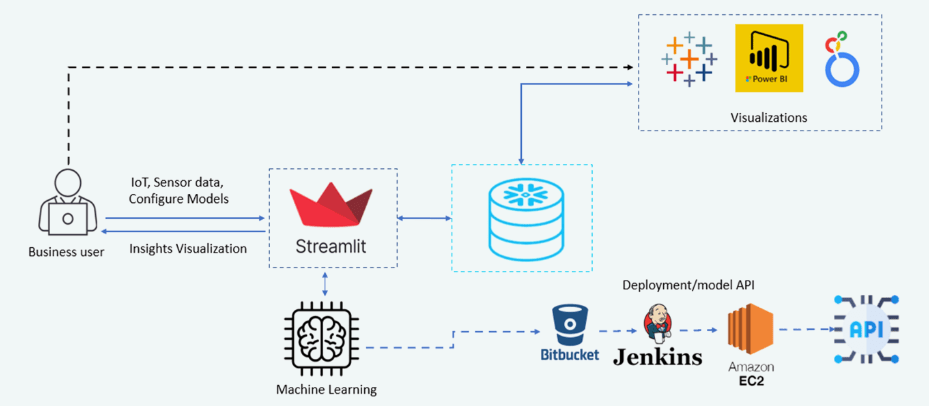

Architecture Diagram of Predictive Maintenance Accelerator

Get Started with the Predictive Maintenance Accelerator

Learn how Boolean can help you reduce costs and optimise performance while ensuring control and compliance.

Request For Demo

Get Started with the Predictive Maintenance Accelerator

About Boolean Data

Systems

Boolean Data Systems is a Snowflake Select Services partner that implements solutions on cloud platforms. we help enterprises make better business decisions with data and solve real-world business analytics and data problems.

Services and

Offerings

Solutions &

Accelerators

Global

Head Quarters

1255 Peachtree Parkway, Suite #4204, Alpharetta, GA 30041, USA.

Ph. : +1 678-261-8899

Fax : (470) 560-3866